01 Me yasa wuyar warwarewa

Bayan an ƙera allon kewayawa, ana buƙatar sanya abubuwan haɗin gwiwa akan layin guntu na SMT. Kowace masana'antar sarrafa SMT za ta ƙayyade mafi girman girman da'ira bisa ga bukatun aiki na layin taro. Alal misali, girman ya yi ƙanƙara ko babba, kuma an daidaita layin taro. Ba za a iya gyara kayan aiki na allon kewayawa ba.

Sai tambaya ta taso, shin idan girman hukumar da’irar mu ita kanta ya kai girman da masana’anta ke bayarwa? Wato muna buƙatar haɗa allon kewayawa tare da haɗa allunan da'ira da yawa a cikin gaba ɗaya. Ƙaddamarwa na iya inganta haɓakawa sosai don injunan jeri mai sauri da kuma siyar da igiyoyin ruwa.

02 Bayanin wuyar warwarewa

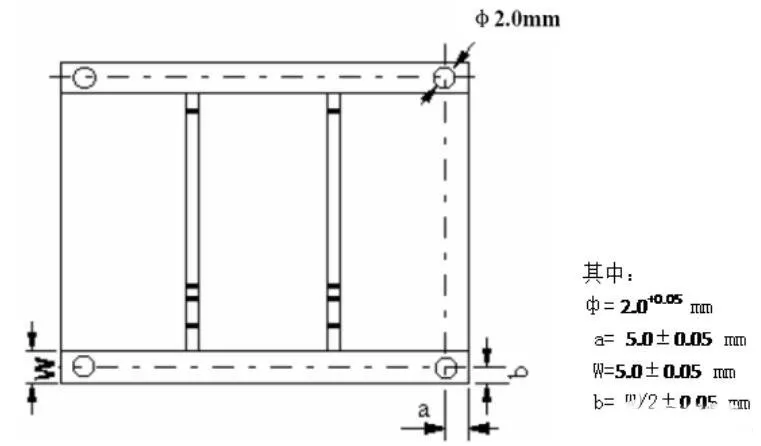

○ Girma

a. Don dacewar sarrafawa, kusurwar allon veneer ko gefen sana'a ya kamata ya zama chamfer nau'in R. Gabaɗaya, madaidaicin kusurwar kusurwa shine Φ5.

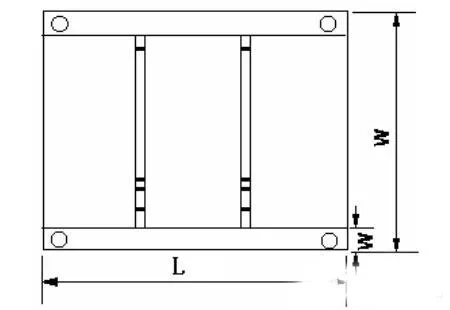

b. Lokacin da girman allo bai wuce 100mm × 70mm, PCB ya kamata a haɗa (duba Hoto 3.1).

Bukatun girma na wasan wasa:

Tsawon L: 100mm ~ 400mm

Nisa W: 70mm ~ 400mm

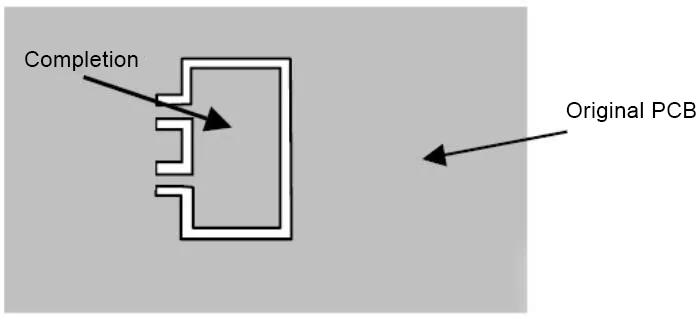

○ PCB mara ka'ida

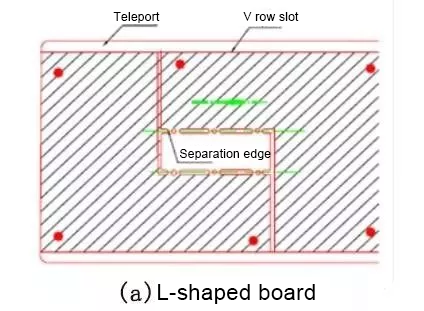

PCBs masu sifofi marasa tsari kuma babu jigs yakamata su sami gefuna na fasaha. Idan PCB yana da ramuka masu girma fiye da ko daidai da 5mm × 5mm, dole ne a kammala ramukan yayin ƙira don guje wa siyarwa da nakasar allo yayin siyarwa. Sashe na gaba da ainihin ɓangaren PCB yakamata su kasance a gefe ɗaya Haɗa kuma cire shi bayan sayar da igiyoyin ruwa (duba Hoto 3.2)

Lokacin da haɗin tsakanin gefen tsari da PCB shine tsagi mai siffar V, nisa tsakanin gefen waje na na'urar da tsagi mai siffar V shine ≥2mm; lokacin da haɗin tsakanin gefen tsari da PCB shine rami mai hatimi, na'urori da layi ba a yarda a shirya su a cikin 2mm a kusa da ramin hatimi.

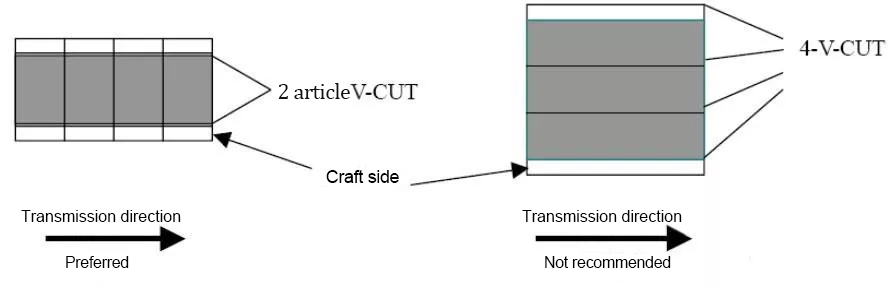

○ wuyar warwarewa

Ya kamata a tsara alkiblar jigsaw daidai da jagorancin gefen isarwa. Lokacin da girman ba zai iya saduwa da buƙatun da ke sama don girman ƙaddamarwa ba, banda shine. Gabaɗaya yana buƙatar “V-CUT” ko adadin layin rami na tambari ≤ 3 (sai dai siriri mai laushi), duba Hoto 3.4

Don allon mai siffa na musamman, kula da alaƙar da ke tsakanin allon 'yar mata da allon 'yar, kuma kuyi ƙoƙarin yin haɗin gwiwa a kowane mataki da aka rabu akan layi, kamar yadda aka nuna a hoto 3.5.

03 pcb wuyar warwarewa saman batutuwa goma masu buƙatar kulawa

A karkashin al'ada yanayi, PCB samar za a kira abin da ake kira Panelization (Panelization) aiki, manufar ita ce ƙara samar da yadda ya dace na SMT samar line, sa'an nan PCB PCB, abin da cikakken bayani ya kamata mu kula? Mu duba tare.

1. Firam ɗin waje (ƙuƙwalwar gefen) na wasan caca na PCB yakamata ya ɗauki ƙirar madauki mai rufaffiyar don tabbatar da cewa wasan cacar PCB ba zai zama naƙasa ba bayan an gyara shi akan kayan aiki.

2. Siffar wasan wasa na PCB yana kusa da murabba'i kamar yadda zai yiwu. Ana ba da shawarar yin amfani da 2 × 2, 3 × 3,….

3. PCB panel nisa ≤260mm (layin SIEMENS) ko ≤300mm (layin FUJI); idan ana buƙatar rarraba ta atomatik, nisa panel PCB × tsawon≤125mm × 180mm.

4. Kowane ƙaramin allo a cikin wuyar warwarewa na PCB dole ne ya kasance yana da aƙalla ramuka guda uku, 3 ≤ budewa ≤ 6 mm, wiring ko faci ba a yarda da shi a cikin 1 mm na ramukan matsayi na gefen.

5. Tsakanin tsakiya tsakanin ƙananan faranti yana sarrafawa tsakanin 75mm ~ 145mm.

6. A lokacin da kafa tunani sakawa batu, yawanci barin wani solderless yanki 1.5mm girma fiye da sakawa batu.

7. Kada a sami manyan na'urori ko na'urori masu tasowa kusa da wuraren haɗin kai tsakanin firam ɗin waje na wuyar warwarewa da ƙaramin allo na ciki, da tsakanin ƙaramin allo da ƙaramin allo, kuma ya kamata a sami sarari fiye da 0.5mm tsakanin gefuna na abubuwan da aka gyara da PCB Don tabbatar da cewa kayan aikin yankan yana gudana akai-akai.

8. Ana buɗe ramuka guda huɗu a kusurwoyi huɗu na firam ɗin waje na panel, kuma diamita na rami shine 4mm ± 0.01mm; Dole ne ƙarfin rami ya zama matsakaici don tabbatar da cewa ba zai karye ba a lokacin faranti na sama da na ƙasa. .

9. Alamomin tunani da aka yi amfani da su don matsayi na PCB da matsayi na na'ura mai kyau. A ka'ida, QFPs tare da farar ƙasa da 0.65mm ya kamata a saita su a matsayi na diagonal; alamomin nunin matsayi da aka yi amfani da su don shigar da allunan 'yar PCB ya kamata a haɗa su Amfani, sanya diagonally zuwa kashi na sakawa.

10.Large aka gyara ya kamata a sami matsayi matsayi ko matsayi ramukan, mayar da hankali a kan I / O dubawa, makirufo, baturi dubawa, microcanza, haɗin wayar kai, mota, da dai sauransu.