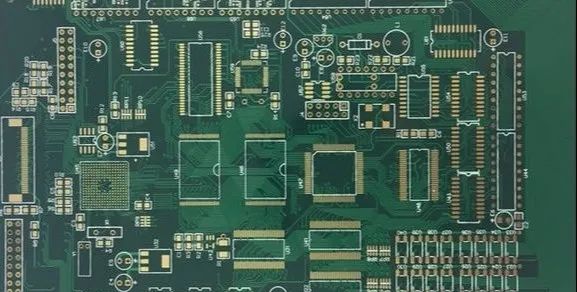

ʻO ke kiʻekiʻe kiʻekiʻe o ka papa kaapuni e pili ana i ka hoʻohana ʻana i ka laulā laina maikaʻi / spacing, nā lua micro, ka laulā apo haiki (a i ʻole ka laulā apo), a me nā lua kanu a me nā makapō e hiki ai ke kiʻekiʻe kiʻekiʻe.

ʻO ka precision kiʻekiʻe e pili ana i ka hopena o ka "ʻili, liʻiliʻi, haiki, lahilahi" e lawe mai i nā koi kikoʻī kiʻekiʻe, e lawe ana i ka laulā laina ma ke ʻano he laʻana: 0.20mm laina laula, e like me nā lula e hana i ka 0.16 ~ 0.24mm e like me ke kūpono, ʻo ka hewa (0.20±0.04) mm; a me ka laula laina o 0.10 mm, ka hewa (0.1±0.02) mm ma ke ala like. ʻIke loa ua pālua ʻia ka pololei o ka hope, a no laila ʻaʻole paʻakikī ke hoʻomaopopo, no laila koi ʻia ka precision kiʻekiʻe ʻAʻole kūkākūkā kaʻawale, akā he pilikia koʻikoʻi i ka ʻenehana hana.

1.Fine ueaʻenehana

I ka wā e hiki mai ana, mai ka 0.20mm a i ka 0.13mm a hiki i ka 0.08mm a hiki i ka 0.005mm ka laina laina kiʻekiʻe kiʻekiʻe e hoʻokō i nā koi o SMT a me nā pūʻulu multi-chip (Mulitichip Package, MCP). No laila, pono nā ʻenehana penei:

①E hoʻohana ana i ka ipu keleawe lahilahi a i ʻole ultra-thin copper foil (<18um) substrate a me ka ʻenehana lapaʻau maikaʻi.

②Me ka hoʻohana ʻana i kahi kiʻiʻoniʻoni maloʻo ʻoi aku ka lahilahi a me ke kaʻina hana lamination pulu, ʻoi aku ka maikaʻi o ke kiʻi ʻoniʻoni maloʻo hiki ke hōʻemi i ka distortion ākea o ka laina a me nā hemahema. Hiki i ke kiʻi ʻoniʻoni ke hoʻopiha i kahi ākea liʻiliʻi, hoʻonui i ka pili o ka interface, a hoʻomaikaʻi i ka pono a me ka pololei o ka uea.

③Hoʻohana ʻia ka photoresist electrodeposited (ED). Hiki ke hoʻomalu ʻia kona mānoanoa ma ka laulā o 5 ~ 30/um, hiki ke hana i nā uea maikaʻi maikaʻi loa. He kūpono loa ia no ka laulā apo haiki, ʻaʻohe laulā apo a me ka hoʻopaʻa paʻa piha. I kēia manawa, ʻoi aku ma mua o ʻumi mau laina hana ED ma ka honua.

④Hoʻohana i ka ʻenehana hōʻike māmā like. No ka mea hiki i ka ʻike kukui like ke lanakila i ka mana o ka hoʻololi ʻana o ka laulā laina ma muli o ke kukui oblique o ke kumu kukui "point", hiki ke loaʻa kahi uea maikaʻi me ka laulā laina pololei a me nā ʻaoʻao maʻalahi. Eia nō naʻe, ʻoi aku ke kumukūʻai o nā mea hana hoʻolaha like, pono ke hoʻopukapuka kiʻekiʻe, a pono e hana i kahi ʻano maʻemaʻe kiʻekiʻe.

⑤E hoʻohana i ka ʻenehana ʻike maka. Ua lilo kēia ʻenehana i mea koʻikoʻi no ka ʻike ʻana i ka hana ʻana i nā uea maikaʻi a ke hāpai wikiwiki ʻia nei, hoʻohana ʻia a hoʻomohala ʻia.

2.Micropore ʻenehana

Hoʻohana nui ʻia nā puka hana o nā papa i paʻi ʻia i luna no ka hoʻopili uila, ʻo ia ka mea e ʻoi aku ka nui o ka noi ʻana o ka ʻenehana micro-hole. ʻO ka hoʻohana ʻana i nā mea drill bit maʻamau a me nā mīkini wili CNC e hana i nā lua liʻiliʻi he nui nā hemahema a me nā kumukūʻai kiʻekiʻe.

No laila, hana nui ʻia nā papa kaapuni paʻi kiʻekiʻe e nā uea maikaʻi a me nā pads. ʻOiai ua loaʻa nā hopena nui, ua kaupalena ʻia ko lākou hiki. No ka hoʻomaikaʻi hou ʻana i ka density (e like me nā uea ma lalo o 0.08 mm), ua piʻi nui ke kumukūʻai No laila, hoʻohana ʻia nā micro-pores e hoʻomaikaʻi i ka densification.

I nā makahiki i hala iho nei, ua hana ʻia nā holomua i ka ʻenehana o nā mīkini drilling CNC a me nā micro-bits, no laila ua ulu wikiwiki ka ʻenehana micro-hole. ʻO kēia ka hiʻohiʻona koʻikoʻi nui i ka hana PCB o kēia manawa.

I ka wā e hiki mai ana, ʻo ka ʻenehana o ka hana ʻana i nā micro-hole e hilinaʻi nui i nā mīkini wili CNC holomua a me nā poʻo micro-poʻo. ʻO nā puka liʻiliʻi i hana ʻia e ka ʻenehana laser ʻoi aku ka liʻiliʻi ma mua o nā lua liʻiliʻi i hana ʻia e nā mīkini wili CNC mai ka ʻike o ke kumukūʻai a me ka maikaʻi o ka lua.

①CNC wili mīkini

I kēia manawa, ua hana ʻo CNC drilling machine i nā holomua hou a me ka holomua. A hoʻokumu i kahi hanauna hou o CNC drilling machine i hōʻike ʻia e ka wili ʻana i nā lua liʻiliʻi.

ʻO ka maikaʻi o ka hoʻoheheʻe ʻana i nā lua liʻiliʻi (ma lalo o 0.50mm) i nā mīkini hoʻoheheʻe micro-hole he 1 mau manawa kiʻekiʻe ma mua o nā mīkini wili CNC maʻamau, me ka liʻiliʻi o nā hemahema, a ʻo ka wikiwiki ʻo 11-15r / min; Hiki ke wili ʻia nā lua micro 0.1-0.2mm. Hiki ke wili ʻia ke kiʻekiʻe kiʻekiʻe kiʻekiʻe kiʻekiʻe wili liʻiliʻi ma ka hoʻopaʻa ʻana i ʻekolu mau papa (1.6mm/piece).

Ke haki ka drill bit, hiki iā ia ke ho'ōki 'akomi a hōʻike i ke kūlana, hoʻololi 'akomi i ka drill bit a nānā i ke anawaena (hiki i ka waihona mea hana ke hoʻokomo i nā haneli haneli), a hiki ke hoʻomalu 'akomi i ka mamao mau a me ka hohonu wili o ka piko drill a ka pā uhi, i hiki ke wili ʻia nā puka makapō , ʻAʻole e wili i ka papaʻaina.

Hoʻohana ka papa ʻaina o ka mīkini drilling CNC i ka cushion air a me ke ʻano levitation magnetic, e neʻe wikiwiki ana, ʻoi aku ka māmā a me ka pololei me ka ʻole o ka ʻoki ʻana i ka papaʻaina. Ua kaulana loa ia mau mīkini wiliwili i kēia manawa, e like me Mega 4600 mai Prurite ma Italia, Excellon 2000 series ma United States, a me nā huahana hanauna hou e like me Switzerland a me Kelemānia.

②He nui nā pilikia me ka ʻeli ʻana i nā mīkini CNC maʻamau a me nā bits e wili ai i nā lua micro. Ua pale ia i ka holomua o ka ʻenehana micro-hole, no laila ua loaʻa ka nānā ʻana, ka noiʻi a me ka noi ʻana o ka laser erosion.

Akā, aia kahi kīnā make, ʻo ia hoʻi, ka hoʻokumu ʻana o nā puka pepeiaohao, e lilo i mea koʻikoʻi i ka piʻi ʻana o ka mānoanoa o ka papa. Hoʻohui ʻia me ka hoʻohaumia ʻana i ka wela (ʻoi aku ka nui o nā papa he nui), ke ola a me ka mālama ʻana i nā kumu kukui, ka pololei o ka hana hou ʻana o nā lua i kālai ʻia, a me nā kumukūʻai, ua kaupalena ʻia ka hoʻolaha ʻana a me ka hoʻohana ʻana i nā lua micro ma nā papa i paʻi ʻia.

Eia nō naʻe, hoʻohana mau ʻia nā lua i kālai ʻia i ka laser i nā microplates lahilahi kiʻekiʻe, ʻoi aku ka nui o ka ʻenehana MCM-L high-density interconnect (HDI), e like me ka polyester film etched hole a me ka deposition metala ma MCMS (Sputtering technology) i hui pū ʻia me ka kiʻekiʻe. -e pili ana i ka density.

Hiki ke hoʻohana ʻia ke kūkulu ʻana i nā lua i kanu ʻia i nā papa multilayer kiʻekiʻe i hoʻopili ʻia me nā hale kanu a me nā puka makapō. Eia nō naʻe, ma muli o ka hoʻomohala ʻana a me nā ʻenehana ʻenehana o nā mīkini drilling CNC a me nā micro-drills, ua hoʻolaha koke ʻia lākou a hoʻohana ʻia.

No laila, ʻaʻole hiki i ka hoʻohana ʻana i ka hoʻoheheʻe ʻana i ka laser ma nā papa kaapuni mauna i kahi kūlana mana. Akā, aia kahi wahi ma kekahi wahi.

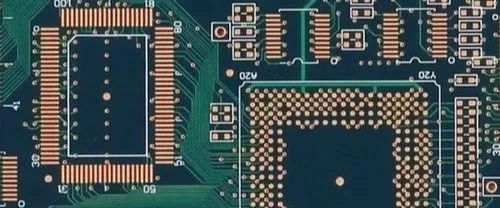

③ kanu ʻia, makapō, ʻenehana ma loko o ka lua i kanu ʻia, makapō, ʻenehana hui pū ʻana ma loko o ka puka he ala nui hoʻi e hoʻonui ai i ka nui o nā kaapuni paʻi.

ʻO ka maʻamau, ʻo nā lua i kanu ʻia a me nā puka makapō he mau puka liʻiliʻi. Ma waho aʻe o ka hoʻonui ʻana i ka helu o nā uwila ma ka papa, hoʻohana nā lua i kanu ʻia a me nā makapō i ka "kokoke" inter-layer interconnection, kahi e hōʻemi nui ai i ka helu o nā puka i hana ʻia a ʻo ka hoʻonohonoho kaʻawale ʻana hoʻi e hoʻemi nui ʻia, ma laila e hoʻonui ai i ka ka helu o nā wili maikaʻi a me nā pilina ma waena o ka papa, a me ka hoʻonui ʻana i ka nui o nā pilina.

No laila, ʻo ka papa multi-layer i hui pū ʻia me nā lua i kanu ʻia, nā makapō, a me nā puka ma ka liʻiliʻi o 3 mau manawa kiʻekiʻe ma mua o ka papa hana maʻamau piha-ma-puka ma ka nui like a me ka helu o nā papa. Inā kanu ʻia, makapō, a ʻO ka nui o ka papa paʻi i hui pū ʻia me nā puka e hoʻemi nui ʻia a i ʻole ka nui o nā papa e hoʻemi nui ʻia.

No laila, ma nā papa paʻi paʻi kiʻekiʻe kiʻekiʻe, ua hoʻohana nui ʻia nā ʻenehana i kanu ʻia a me nā puka makapō, ʻaʻole wale ma nā papa i paʻi ʻia i luna i nā kamepiula nui a me nā lako kamaʻilio, akā i nā noi kīwila a me nā ʻoihana. Ua hoʻohana nui ʻia ma ke kula, ʻo ia hoʻi i kekahi mau papa lahilahi, e like me nā PCMCIA, Smard, IC kāleka a me nā papa ʻeono ʻāpana ʻē aʻe.

ʻO nā papa kaapuni i paʻi ʻia me nā hale kanu a me nā puka makapō e hoʻopau ʻia e ke ʻano hana "sub-board", ʻo ia ka mea hiki ke hoʻopau ʻia ma hope o ka nui o nā papa paʻi, wili, hole plating, etc., no laila he mea koʻikoʻi ke kūlana pololei.