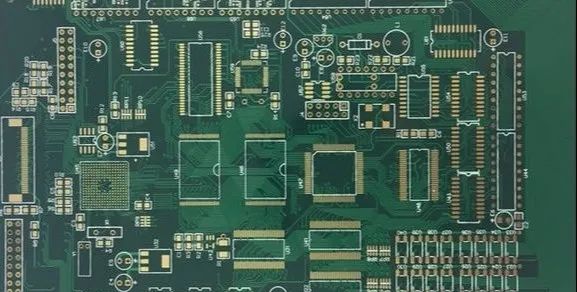

Lub siab precision ntawm lub rooj tsavxwm Circuit Court yog hais txog kev siv cov kab dav dav / qhov sib txawv, qhov micro qhov, lub nplhaib nqaim dav (lossis tsis muaj lub nplhaib dav), thiab faus thiab qhov muag tsis pom qhov kom ua tiav qhov siab ceev.

Lub siab precision hais txog qhov tshwm sim ntawm "nyias, me, nqaim, nyias" yuav inevitably nqa high precision yuav tsum, noj cov kab dav raws li piv txwv: 0.20mm kab dav, raws li cov kev cai los tsim 0.16 ~ 0.24mm raws li tsim nyog, Qhov yuam kev yog (0.20 ± 0.04) mm; thiab kab dav ntawm 0.10 hli, qhov yuam kev yog (0.1 ± 0.02) mm nyob rau hauv tib txoj kev. Pom tseeb qhov tseeb ntawm qhov kawg yog ob npaug, thiab yog li ntawd tsis yooj yim rau kev nkag siab, yog li qhov siab precision yuav tsum tsis txhob sib tham ntxiv lawm, tab sis nws yog ib qho teeb meem tseem ceeb hauv kev siv tshuab ntau lawm.

1.Fine hlau technology

Nyob rau hauv lub neej yav tom ntej, cov high-density kab dav / qhov sib txawv yuav yog los ntawm 0.20mm mus rau 0.13mm mus rau 0.08mm mus rau 0.005mm kom tau raws li cov kev cai ntawm SMT thiab multi-chip pob (Mulitichip Package, MCP). Yog li ntawd, cov technologies hauv qab no yuav tsum tau:

①Siv nyias los yog ultra-thin copper foil (<18um) substrate thiab zoo nto kho tshuab.

②Siv cov yeeb yaj kiab nyias nyias thiab cov txheej txheem lamination ntub, nyias thiab zoo zoo qhuav zaj duab xis tuaj yeem txo cov kab dav distortion thiab tsis xws luag. Cov yeeb yaj kiab ntub dej tuaj yeem ua rau qhov sib txawv me me, ua kom muaj kev sib txuas ua ke, thiab txhim kho cov hlau kev ntseeg siab thiab raug.

③ Electrodeposited photoresist (ED) yog siv. Nws cov tuab tuaj yeem tswj tau hauv thaj tsam ntawm 5 ~ 30 / um, uas tuaj yeem tsim cov xov hlau zoo tshaj plaws. Nws yog tshwj xeeb tshaj yog haum rau nqaim nplhaib dav, tsis muaj nplhaib dav thiab tag nrho-phaj plating. Tam sim no, muaj ntau tshaj kaum ED cov kab ntau lawm hauv ntiaj teb.

④ Txais kev siv hluav taws xob sib luag. Txij li thaum lub teeb pom kev sib luag tuaj yeem kov yeej qhov cuam tshuam ntawm kab dav qhov sib txawv los ntawm oblique lub teeb ntawm "point" lub teeb ci, cov hlau zoo nrog cov kab dav dav thiab cov npoo du tuaj yeem tau txais. Txawm li cas los xij, cov khoom siv sib xyaw ua ke yog kim, xav tau kev nqis peev siab, thiab yuav tsum tau ua haujlwm hauv qhov chaw huv huv.

⑤ Txais kev siv tshuab kho qhov muag tsis siv neeg. Cov thev naus laus zis no tau dhau los ua qhov tseem ceeb ntawm kev tshawb nrhiav hauv kev tsim cov xov hlau zoo thiab tau txais kev txhawb nqa sai, siv thiab tsim.

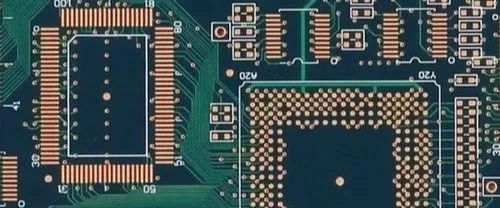

2.Micropore technology

Lub qhov ua haujlwm ntawm cov ntawv luam tawm saum npoo av yog siv rau kev sib txuas hluav taws xob, uas ua rau daim ntawv thov ntawm micro-qhov tshuab tseem ceeb dua. Kev siv cov khoom siv tho me me thiab CNC drilling tshuab los tsim cov qhov me me muaj ntau yam tsis ua haujlwm thiab cov nqi siab.

Yog li ntawd, high-density printed circuit boards feem ntau yog ua los ntawm cov xov hlau zoo thiab cov ntaub qhwv. Txawm hais tias tau txais txiaj ntsig zoo, lawv lub peev xwm raug txwv. Txhawm rau txhim kho qhov ceev ntxiv (xws li cov xov hlau tsawg dua 0.08 hli), tus nqi tau nce siab heev Yog li ntawd, micro-pores yog siv los txhim kho qhov ntom ntom.

Nyob rau hauv xyoo tas los no, kev ua tiav tau ua tiav hauv kev siv tshuab CNC drilling tshuab thiab micro-ntsis, yog li cov tshuab micro-qhov tau tsim sai heev. Qhov no yog qhov tseem ceeb tshaj plaws hauv kev tsim khoom PCB tam sim no.

Nyob rau hauv lub neej yav tom ntej, thev naus laus zis ntawm kev tsim micro-qhov yuav tsuas yog vam khom CNC drilling tshuab thiab zoo micro-taub hau. Cov qhov me me uas tsim los ntawm cov tshuab laser tseem tsis zoo rau cov qhov me me uas tsim los ntawm CNC drilling tshuab los ntawm kev pom ntawm tus nqi thiab qhov zoo.

① CNC drilling tshuab

Tam sim no, CNC drilling tshuab thev naus laus zis tau ua tiav tshiab thiab kev vam meej. Thiab tsim ib lub cim tshiab ntawm CNC drilling tshuab yam ntxwv los ntawm drilling qhov me me.

Qhov ua tau zoo ntawm qhov drilling qhov me me (tsawg dua 0.50mm) hauv cov tshuab micro-qhov drilling yog 1 zaug siab dua li cov pa CNC drilling tshuab, nrog tsawg dua kev ua haujlwm, thiab qhov ceev yog 11-15r / min; 0.1-0.2 hli micro qhov tuaj yeem drilled. Qhov zoo tshaj plaws zoo me me laum me me tuaj yeem raug laum los ntawm stacking peb daim hlau (1.6mm / thooj).

Thaum lub laum me ntsis tawg, nws tuaj yeem nres thiab tshaj tawm txoj haujlwm, tuaj yeem hloov lub laum me ntsis thiab tshawb xyuas txoj kab uas hla (lub tsev qiv ntawv cov cuab yeej tuaj yeem ua tau ntau pua daim), thiab tuaj yeem tswj tau qhov kev ncua deb thiab drilling qhov tob ntawm lub laum taub thiab lub npog phaj, kom qhov muag tsis pom qhov yuav tau drilled, Yuav tsis laum lub rooj.

Lub rooj ntawm CNC drilling tshuab txais cua cushion thiab magnetic levitation hom, uas txav ceev dua, sib dua thiab ntau dua yam tsis tau khawb lub rooj. Xws li cov tshuab drilling tam sim no nrov heev, xws li Mega 4600 los ntawm Prurite hauv ltalis, Excellon 2000 series hauv Tebchaws Meskas, thiab cov khoom tsim tshiab xws li Switzerland thiab Lub Tebchaws Yelemees.

② Muaj qhov tseeb ntau yam teeb meem nrog laser drilling pa CNC drilling tshuab thiab cov khoom rau laum micro qhov. Nws tau cuam tshuam qhov kev nce qib ntawm micro-qhov tshuab, yog li laser yaig tau txais kev mloog, kev tshawb fawb thiab kev siv.

Tab sis muaj qhov tsis txaus ntshai, uas yog, tsim ntawm lub qhov taub, uas ua rau hnyav dua thaum lub thickness ntawm lub rooj tsavxwm nce. Coupled nrog kub ablation muaj kuab paug (tshwj xeeb tshaj yog multi-txheej boards), lub neej thiab txij nkawm ntawm lub teeb qhov chaw, qhov rov raug ntawm etched qhov, thiab cov nqi, kev nce qib thiab daim ntawv thov ntawm micro qhov nyob rau hauv cov ntawv luam tawm yog txwv.

Txawm li cas los xij, laser etched qhov tseem siv nyob rau hauv nyias high-density microplates, tshwj xeeb tshaj yog nyob rau hauv MCM-L high-density interconnect (HDI) technology, xws li polyester zaj duab xis etched qhov thiab hlau deposition nyob rau hauv MCMS (Sputtering technology) yog siv nyob rau hauv ua ke nrog nrog siab. - ceev sib txuas.

Kev tsim ntawm faus qhov nyob rau hauv high-density interconnected multilayer boards nrog faus thiab qhov muag tsis pom qhov qauv kuj yuav siv tau. Txawm li cas los xij, vim yog kev txhim kho thiab thev naus laus zis ntawm CNC drilling tshuab thiab micro-drills, lawv tau nrawm nrawm thiab thov.

Yog li ntawd, daim ntawv thov ntawm laser drilling nyob rau hauv nto mount Circuit Court boards tsis tuaj yeem tsim ib txoj hauj lwm tseem ceeb. Tab sis tseem muaj qhov chaw nyob hauv ib cheeb tsam.

③ faus, qhov muag tsis pom, los ntawm lub qhov tshuab faus, qhov muag tsis pom kev, los ntawm qhov sib xyaw tshuab kuj yog ib txoj hauv kev tseem ceeb los ua kom cov ntawv luam tawm ntau dua.

Feem ntau, qhov faus thiab qhov muag tsis pom yog qhov me me. Ntxiv nrog rau kev nce cov xov tooj ntawm lub rooj tsavxwm, qhov faus thiab qhov muag tsis pom kev siv qhov "ze" cov txheej txheem kev sib txuas, uas txo cov naj npawb ntawm cov qhov tsim thiab cov phaj sib cais kuj tseem yuav txo qis, yog li ua kom muaj qhov sib txawv ntawm qhov sib txawv. tus naj npawb ntawm cov kab hluav taws xob zoo thiab cov txheej txheem kev sib tshuam hauv lub rooj tsavxwm, thiab ua kom qhov ceev ntawm kev sib tshuam.

Yog li ntawd, cov txheej txheem ntau txheej ua ke nrog faus, qhov muag tsis pom, thiab dhau ntawm qhov muaj qhov sib cuam tshuam ntawm qhov tsawg kawg yog 3 npaug siab dua li cov qauv ntawm cov khoom siv puv-dhau-qhov board ntawm tib qhov loj thiab cov txheej txheem. Yog tias faus, qhov muag tsis pom, thiab qhov loj ntawm cov ntawv luam tawm ua ke nrog los ntawm qhov yuav raug txo kom tsawg lossis cov txheej txheem yuav raug txo kom tsawg.

Yog li ntawd, nyob rau hauv high-density nto-mounted luam ntawv boards, faus thiab dig qhov muag technologies yog nce siv, tsis tsuas yog nyob rau hauv nto-mounted luam ntawv boards nyob rau hauv loj computers thiab cov khoom siv sib txuas lus, tab sis kuj nyob rau hauv pej xeem thiab kev siv. Nws kuj tau siv dav hauv thaj chaw, txawm tias nyob rau hauv qee qhov nyias nyias, xws li ntau yam PCMCIA, Smard, IC phaib thiab lwm cov ntawv nyias rau txheej.

Cov ntawv luam tawm Circuit Board nrog faus thiab qhov muag tsis pom cov qauv feem ntau ua tiav los ntawm "sub-board" txoj kev tsim khoom, uas txhais tau hais tias nws tuaj yeem ua tiav tom qab ntau daim hlau nias, drilling, qhov plating, thiab lwm yam., yog li qhov tseeb yog qhov tseem ceeb heev.