After a period of intense and orderly installation, commissioning and equipment operation training,the SMT production line of Shenzhen HDV photoelectron technology Co., LTD was officially put into production on August 15,2019.Prior to this, through complete SMT production of the board, the equipment operator was further familiar with the operation flow and operation points of the entire equipment.At present, the operation condition is good.

SMT (Surface Mounted Technology) is currently the most popular technology and process in the electronics assembly industry.From the visit to the SMT workshop,the SMT production process mainly includes several important processes such as GKG automatic printing machine, Japan JUKI placement machine, reflow soldering, Shenzhou vision AOI, DIP wave soldering.The strict and precise execution of each process is a prerequisite for ensuring product quality.

1.Introduction to major equipment:

⑴.GKG automatic printing machine:

With solder paste printing offset, automatic printing detection function, can prevent and control 70% of common defects in SMT operations.

Send one machine, automatic suction plate, transfer PCB to the next station (automatic printing machine)

⑵.Japan JUKI Mounter:

The universal machine is equipped with a high-precision camera that can identify BGA and QFN type bottom solder fillets, or 0.4MM pitch high integrated SOP and PLCC.

Japan JUKI KE-2060 Mounter

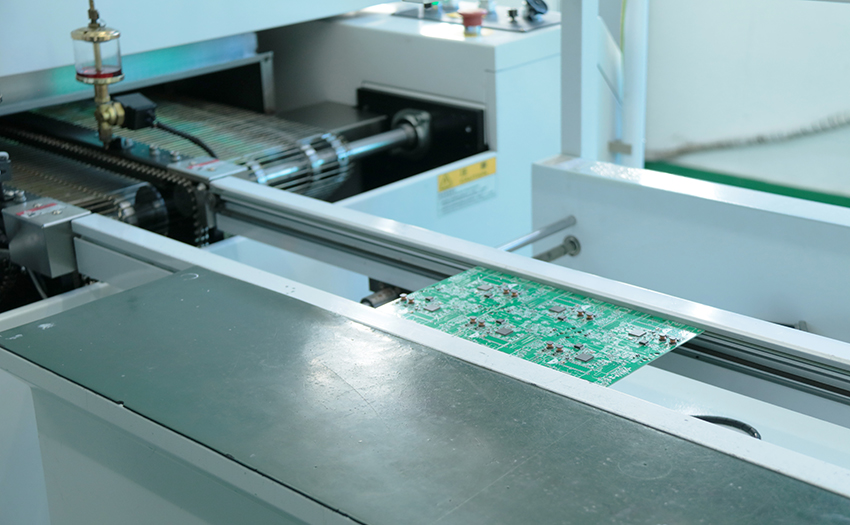

⑶.Reflow soldering:

PCB maximum width: 500MM.

Temperature zone: Eight temperature zone independent and precise temperature control, adapt to all kinds of PCB boards, components and processes.

After the reflow soldering, it enters the cooling step and can also be temporarily stored. This process can temporarily store 20pcs.

⑷.Shenzhou Vision AOI

Fully automatic optical inspection after furnace, with 0.6*0.3MM (0201) component detection capability, Japan Ricoh 3CCD color camera can accurately identify the color change of each component, and compare and detect badly by comparison analysis, processing 180 detection points per second, fast Delivery and quality control are guaranteed.

The AOI detector can detect the type of the component and the welding effect by automatically detecting the good product and the defective product.

2.Production line capacity

Each line can produce parts types: 120 types of front, 80 types of rear, and 40 types of universal MTS disc feeders for uninterrupted use, totaling 240 kinds of parts.

Capacity: 60000CPH per line, calculated at 150 points per PCBA, can produce 400pcs per hour, and can produce PCBA 8000pcs per day for 20 hours.

With the launch of the new production line, the company will greatly shorten the time in research and development of prototype production and customer order production. The lead time of most products can be controlled within one week.

The introduction of the SMT production line will effectively solve the welding problem of some parts that cannot be manually soldered during the electrical installation process of our company, and greatly improve the efficiency of electric installation work, welding quality and inspection quality.