VCSEL, which is called a Vertical Cavity Surface Emitting Laser in full, is a kind of semiconductor laser. Currently, most VCSELs are based on GaAs semiconductors, and the emission wavelength is mainly in the infrared wave band.

In 1977, Professor Ika Kenichi of Tokyo University of Technology first proposed the concept of a vertical-cavity surface-emitting laser. In the early days, he mainly wanted to obtain a single longitudinal mode semiconductor laser with stable output by shortening the cavity length. However, due to this design’s short one-way gain length, it was challenging to obtain laser lasing, so the early research of VCSEL was prolonged. Two years later, Professor Yihe Jianyi successfully realized pulsed lasing of GaInAsP series lasers at 77 K using liquid phase epitaxy technology (the method of liquid-phase epitaxy to precipitate solid substances from solution and deposit them on the substrate to generate single-crystal thin layers). In 1988, GaAs series VCSELs were grown by organic chemical vapor deposition (OCVD) technology to achieve continuous operation at room temperature. With the constant development of epitaxial technology, semiconductor DBR structures with high reflectivity can be manufactured, which significantly speeds up the research process of VCSEL. At the end of the 20th century, after research institutions had tried out different structures, the mainstream status of oxidation-limited VCSEL was pretty much set. It then moved into the stage of maturity, where performance was constantly optimized and improved.

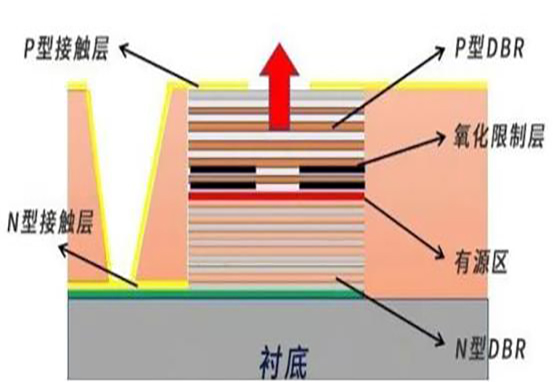

Sectional diagram of oxidation limited top emitting laser

The active region is the essential part of the device. Because the VCSEL cavity is very short, the active medium in the cavity needs to provide more gain compensation for the lasing mode.

First of all, three conditions must be met simultaneously to generate a laser:

1) the carrier inversion distribution in the active region is established;

2) a suitable resonant cavity allows the stimulated radiation to be fed back many times to form a laser oscillation; and

3) the current injection is strong enough to make the optical gain greater than or equal to the sum of various losses and meet certain current threshold conditions.

The three primary conditions correspond to the design concept of the VCSEL device structure. The active region of VCSEL uses a strained quantum well structure to establish the basis for realizing the internal carrier inversion distribution. At the same time, a resonant cavity with appropriate reflectivity is designed to make the emitted photons form coherent oscillations. Finally, sufficient injection current is provided to enable photons to overcome various losses of the device itself to create a lasting

This is how Shenzhen HDV Optoelectronic Technology Co., Ltd., an optical communication company, explained VCSEL.