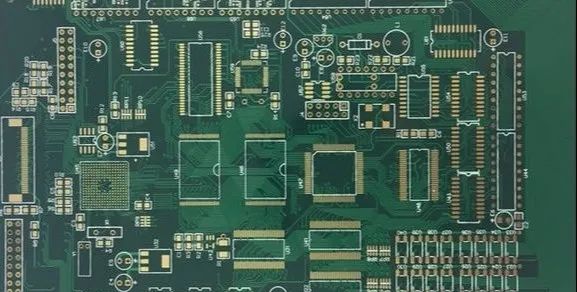

Ukuchaneka okuphezulu kwebhodi yesekethe kubhekiselele ekusetyenzisweni kobubanzi bomgca ocolekileyo / isithuba, imingxuma emincinci, ububanzi obuncinci bomsesane (okanye akukho bubanzi bomsesane), kunye nemingxuma engcwatyiweyo kunye neyimfama ukufezekisa ukuxinana okuphezulu.

Ukuchaneka okuphezulu kubhekiselele kwisiphumo "esincinci, esincinci, esincinci, esincinci," ngokuqinisekileyo siya kuzisa iimfuno ezichanekileyo ezichanekileyo, ukuthatha ububanzi bomgca njengomzekelo: 0.20mm ububanzi bomgca, ngokwemigaqo yokuvelisa i-0.16 ~ 0.24mm njengoko kufanelekile, impazamo ngu (0.20±0.04) mm; kunye nobubanzi bomgca we-0.10 mm, impazamo yi (0.1±0.02) mm ngendlela efanayo. Ngokucacileyo ukuchaneka kokugqibela kuphindwe kabini, kwaye njalo akunzima ukuyiqonda, ngoko ke ukuchaneka okuphezulu kuyafuneka Akusaxoxwa ngokwahlukileyo, kodwa yingxaki evelele kwiteknoloji yokuvelisa.

1.Iteknoloji yocingo oluhle

Kwixesha elizayo, ububanzi/isithuba somgca woxinaniso oluphezulu luya kuba ukusuka kwi-0.20mm ukuya kwi-0.13mm ukuya kwi-0.08mm ukuya kwi-0.005mm ukuhlangabezana neemfuno ze-SMT kunye ne-multi-chip package (i-Mulitichip Package, MCP). Ke ngoko, ezi teknoloji zilandelayo ziyafuneka:

① Ukusebenzisa i-foil yobhedu ebhityileyo okanye ecwecwe kakhulu (<18um) i-substrate kunye neteknoloji yonyango oluphezulu.

② Ukusebenzisa ifilimu eyomileyo eyomileyo kunye nenkqubo yokucoca emanzi, ifilimu eyomileyo kunye neyomgangatho omhle inokunciphisa ukuphambuka kobubanzi kunye neziphene. Ifilimu emanzi inokuzalisa i-gap encinci yomoya, ukwandisa ukunamathela kwi-interface, kunye nokuphucula ingqibelelo yocingo kunye nokuchaneka.

③I-Electrodeposited photoresist (ED) iyasetyenziswa. Ubukhulu bayo bunokulawulwa kuluhlu lwe-5 ~ 30 / um, olunokuvelisa iingcingo ezilungileyo ezigqibeleleyo. Ifaneleke ngakumbi ububanzi obumxinwa bomsesane, akukho bubanzi besangqa kunye neplate epheleleyo. Okwangoku, kukho imigca yemveliso ye-ED engaphezu kweshumi emhlabeni.

④Yamkela itekhnoloji yokuvezwa kokukhanya okuhambelanayo. Ekubeni ukubonakaliswa kokukhanya okuhambelanayo kunokoyisa impembelelo yokuhluka kobubanzi bomgca obangelwa ukukhanya kwe-oblique yomthombo wokukhanya "we-point", ucingo oluhle kunye nobubanzi obuchanekileyo bomgca kunye nemiphetho egudileyo inokufumaneka. Nangona kunjalo, izixhobo zokuvezwa okufanayo ziyabiza, zifuna utyalo-mali oluphezulu, kwaye zifuna ukusebenza kwindawo ecocekileyo.

⑤Yamkela itekhnoloji yokubona ngokuzenzekelayo. Le teknoloji iye yaba yindlela efunekayo yokukhangela kwimveliso yeengcingo ezilungileyo kwaye ikhuthazwa ngokukhawuleza, isetyenziswe kwaye iphuhliswe.

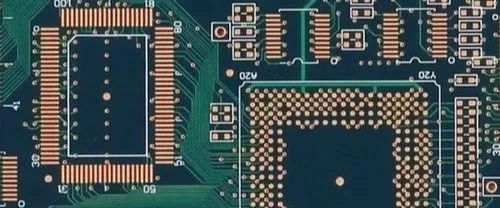

2.Iteknoloji yeMicropore

Imingxuma esebenzayo yeebhodi eziprintiweyo ezifakwe phezulu zisetyenziselwa ukudibanisa kombane, okwenza ukusetyenziswa kweteknoloji ye-micro-hole kubaluleke kakhulu. Ukusetyenziswa kwezixhobo eziqhelekileyo ze-drill kunye noomatshini bokugaya i-CNC ukuvelisa imingxuma emincinci kunokusilela okuninzi kunye neendleko eziphezulu.

Ngoko ke, iibhodi zeesekethe eziprintiweyo eziphakamileyo zenziwe ziingcingo ezintle kunye neepads. Nangona iziphumo ezinkulu zifunyenwe, amandla abo alinganiselwe. Ukuphucula ngakumbi ubuninzi (ezifana neengcingo ezingaphantsi kwe-0.08 mm), iindleko ziphakame ngokukhawuleza Ngoko ke, i-micro-pores isetyenziselwa ukuphucula ukuxinana.

Kwiminyaka yakutshanje, ukuphumelela kuye kwenziwa kwi-teknoloji ye-CNC yokugaya oomatshini kunye ne-micro-bits, ngoko ke iteknoloji ye-micro-hole iphuhliswe ngokukhawuleza. Le yeyona nto ibalaseleyo kwimveliso yePCB yangoku.

Kwixesha elizayo, itekhnoloji yokwenza imingxunya emincinci iya kuthembela kakhulu koomatshini bokugrumba be-CNC kunye neentloko ezincinci ezincinci. Imingxuma emincinci eyenziwe ngeteknoloji ye-laser isengaphantsi kwemingxuma emincinci eyenziwe ngoomatshini bokugaya i-CNC ngokwembono yeendleko kunye nomgangatho womngxuma.

① CNC umatshini wokomba

Okwangoku, itekhnoloji yomatshini wokugrumba i-CNC yenze impumelelo entsha kunye nenkqubela phambili. Kwaye kwaseka isizukulwana esitsha somatshini wokomba we-CNC ophawulwa ngokugrumba imingxunya emincinci.

Ukusebenza kakuhle kokugaya imingxuma emincinci (ngaphantsi kwe-0.50mm) kumatshini wokugaya i-micro-hole kumaxesha angama-1 aphezulu kunoomatshini bokugaya obuqhelekileyo be-CNC, kunye nokungaphumeleli okumbalwa, kunye nesantya se-11-15r / min; I-0.1-0.2mm imingxuma encinci inokugrunjwa. I-drill encinci ekumgangatho ophezulu ekumgangatho ophezulu inokugrunjwa ngokupakisha iipleyiti ezintathu (1.6mm/piece).

Xa i-drill bit iphuka, inokumisa ngokuzenzekelayo kwaye ichaze isikhundla, ibuyisele ngokuzenzekelayo i-drill bit kwaye ikhangele ububanzi (ilayibrari yesixhobo inokusingatha amakhulu amaqhekeza), kwaye inokulawula ngokuzenzekelayo umgama ongaguqukiyo kunye nobunzulu bokomba kwincam ye-drill kunye. icwecwe lokugquma, ukwenzela ukuba imingxuma eyimfama ingagrunjwa , Ayiyi kubhobhoza itafile.

Itheyibhile yomatshini wokugrumba we-CNC wamkela umqamelo womoya kunye nohlobo lwe-magnetic levitation, oluhamba ngokukhawuleza, lube lula kwaye luchaneke ngakumbi ngaphandle kokukrwela itafile. Oomatshini bokwemba abanjalo ngoku bathandwa kakhulu, njengeMega 4600 esuka ePrurite eItali, iExcellon 2000 series eUnited States, kunye neemveliso zesizukulwana esitsha ezifana neSwitzerland neJamani.

②Zininzi iingxaki ngelaser yokomba oomatshini beCNC besiqhelo kunye namasuntswana ukugrumba imingxunya emincinci. Ithintele inkqubela yeteknoloji ye-micro-hole, ngoko ukhukuliseko lwelaser lufumene ingqalelo, uphando kunye nokusetyenziswa.

Kodwa kukho impazamo ebulalayo, oko kukuthi, ukubunjwa kwemingxuma yeempondo, okuba nzima ngakumbi njengoko ubukhulu bebhodi bukhula. Idityaniswe nongcoliseko lobushushu obuphezulu (ngokukodwa iibhodi ezinamanqwanqwa amaninzi), ubomi kunye nokugcinwa kwemithombo yokukhanya, ukuchaneka okuphindaphindiweyo kwemingxuma eqingqiweyo, kunye neendleko, ukukhuthazwa kunye nokusetyenziswa kwemingxuma emincinci kwiibhodi eziprintiweyo zilinganiselwe.

Nangona kunjalo, imingxunya efakwe ngelaser isasetyenziswa kwii-microplates ezibhityileyo ezinoxinzelelo oluphezulu, ngakumbi kwitekhnoloji ye-MCM-L yoxinaniso oluphezulu (HDI), njengemingxunya efakwe kwifilimu yepolyester kunye nokubekwa kwentsimbi kwi-MCMS (itekhnoloji yeSputtering) isetyenziswa ngokudityaniswa nomgangatho ophezulu. -Ukuxinana koqhagamshelwano.

Ukuqulunqwa kwemingxuma engcwatywe kwiibhodi ezininzi ezidityanisiweyo ezidityanisiweyo ezinezakhiwo ezingcwatywe kunye nemingxuma eyimfama nazo zingasetyenziswa. Nangona kunjalo, ngenxa yophuhliso kunye nokuphumelela kwezobuchwepheshe koomatshini bokwemba be-CNC kunye ne-micro-drills, bakhuthazwa ngokukhawuleza kwaye basetyenziswa.

Ke ngoko, ukusetyenziswa kwe-laser drilling kwiibhodi zeesekethe zokunyuka komhlaba akukwazi ukwenza indawo ephezulu. Kodwa kusekho indawo kwindawo ethile.

③ ungcwatywe, uyimfama, itekhnoloji yomngxuma ingcwatywe, imfama, iteknoloji yendibaniselwano yomngxuma ikwayindlela ebalulekileyo yokwandisa ukuxinana kweesekethe eziprintiweyo.

Ngokubanzi, imingxunya engcwatyiweyo neyimfama yimingxuma emincinci. Ukongeza ekunyuseni inani le-wiring ebhodini, imingxuma engcwatywayo kunye neemfama zisebenzisa i-inter-layer interconnection "ekufutshane", enciphisa kakhulu inani lemingxunya eyenziwe kunye nokubeka ipleyiti yodwa iya kuba kakhulu ukuNcitshiswa, ngaloo ndlela ukwandisa inani le-wiring esebenzayo kunye ne-inter-layer interconnections ebhodini, kunye nokwandisa ukuxinana koqhagamshelwano.

Ngoko ke, ibhodi ye-multi-layer edibeneyo kunye nokungcwatywa, ukungaboniyo, kunye ne-mingxuma yokudibanisa i-interconnection density okungenani amaxesha angama-3 aphezulu kunoko kwesakhiwo sebhodi esiqhelekileyo esipheleleyo kwisigxina esifanayo kunye nenani leeleya. Ukuba ungcwatywe, uyimfama, kwaye Ubungakanani bebhodi eprintiweyo edityaniswe nemingxuma iya kuncitshiswa kakhulu okanye inani leeleya liya kuncitshiswa kakhulu.

Ke ngoko, kwiibhodi eziprintiweyo ezixhonywe kumphezulu woxinaniso oluphezulu, itekhnoloji engcwatyiweyo kunye nemngxuma oyimfama isetyenziswa kakhulu, kungekuphela nje kwiibhodi eziprintiweyo eziphezulu kwiikhompyuter ezinkulu kunye nezixhobo zonxibelelwano, kodwa nakwizicelo zoluntu kunye nezoshishino. Ikwasetyenziswa kakhulu ebaleni, nakwiibhodi ezibhityileyo, ezinje ngePCMCIA ezahlukeneyo, iSmard, amakhadi e-IC kunye nezinye iibhodi ezinomaleko ezintandathu.

Iibhodi zesekethe eziprintiweyo ezinezakhiwo ezingcwatyelwe kunye neziyimfama ngokubanzi zigqitywe yindlela yokuvelisa "ibhodi engaphantsi", oku kuthetha ukuba inokugqitywa emva kweeplate ezininzi ezicinezelayo, ukugaya, ukubethelwa kwemingxuma, njl., ngoko ke ukubeka ngokuchanekileyo kubaluleke kakhulu.