01 Kutheni i-Puzzle

Emva kokuba ibhodi yesekethe iyilwe, amacandelo kufuneka abekwe kwi-SMT chip assembly line. Ifektri nganye yokucubungula i-SMT iya kuchaza ubungakanani obufanelekileyo bebhodi yesekethe ngokweemfuno zokulungiswa komgca wendibano. Ngokomzekelo, ubungakanani buncinci okanye bukhulu kakhulu, kwaye umgca wendibano uhleliwe. Isixhobo sebhodi yesekethe ayinakulungiswa.

Emva koko umbuzo uvela, kuthekani ukuba ubungakanani bebhodi yethu yesiphaluka ngokwayo buncinci kunobukhulu obunikwe ngumzi-mveliso? Oko kukuthi, kufuneka sihlanganise ibhodi yesekethe kwaye sihlanganise iibhodi zeesekethe ezininzi zibe yiqhekeza elipheleleyo. Ukubekwa kunokuphucula ngokubonakalayo ukusebenza kakuhle koomatshini bokubekwa ngesantya esiphezulu kunye nokuthengiswa kwamaza.

02 Inkcazo yepuzzle

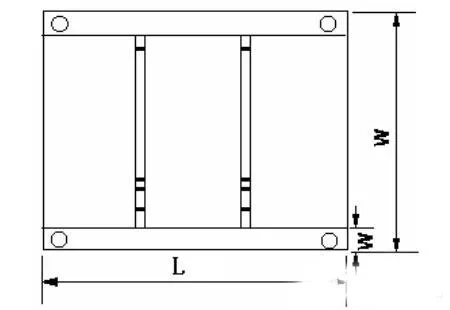

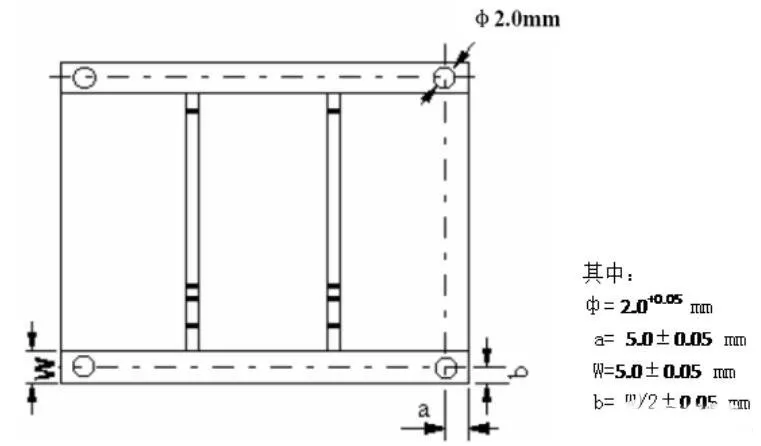

○ Imilinganiselo

a. Ukuze kube lula ukucutshungulwa, i-angle yebhodi ye-veneer okanye i-craft edge kufuneka ibe yi-R-type chamfer. Ngokuqhelekileyo, i-diameter yekona engqukuva yi-Φ5.

b. Xa ubukhulu bebhodi bungaphantsi kwe-100mm × 70mm, i-PCB kufuneka ihlanganiswe (jonga umfanekiso 3.1).

Iimfuno zobungakanani bepuzzle:

Ubude L: 100mm ~ 400mm

Ububanzi W: 70mm ~ 400mm

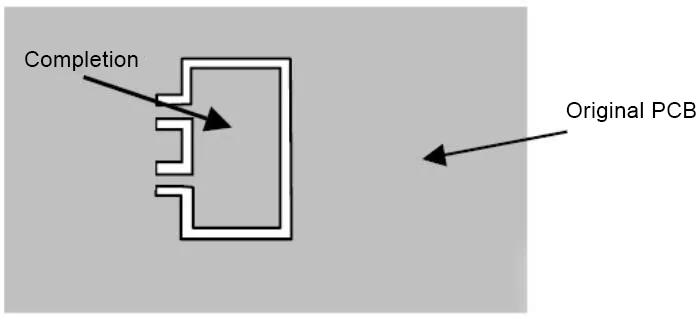

○ I-PCB engaqhelekanga

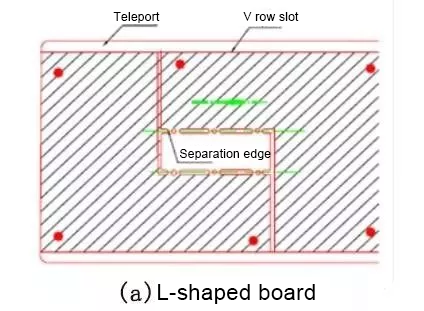

IiPCB ezinemilo engaqhelekanga kwaye akukho jigi kufuneka ibe nemiphetho yezandla. Ukuba i-PCB inemingxuma enobungakanani obukhulu okanye obulingana no-5mm × 5mm, imingxuma kufuneka igqitywe ngexesha loyilo ukuze kugwenywe i-soldering kunye nokuguqulwa kwebhodi ngexesha le-soldering. Inxalenye ehambelanayo kunye neyokuqala yePCB kufuneka ibe kwicala elinye Qhagamshela kwaye uyisuse emva kokuthengiswa kwamaza (jonga umfanekiso 3.2)

Xa uxhulumaniso phakathi komda wenkqubo kunye ne-PCB i-groove efana ne-V, umgama phakathi komda wangaphandle wesixhobo kunye ne-V-shaped groove ngu-≥2mm; xa uxhulumaniso phakathi komphetho wenkqubo kunye ne-PCB ngumngxuma wesitampu, izixhobo kunye nemigca ayivumelekanga ukuba ihlelwe ngaphakathi kwe-2mm malunga nomngxuma wesitampu.

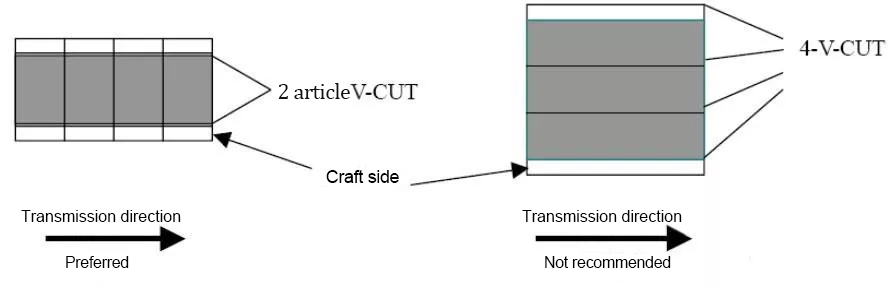

○ Iphazili

Isalathiso sejigsaw kufuneka siyilwe ngokuhambelana nomgca wokuhambisa. Xa ubungakanani bungenako ukuhlangabezana neemfuno ezingentla zobukhulu bokubekwa, okungafaniyo. Ngokubanzi ifuna "i-V-CUT" okanye inani lemigca yomngxuma wesitampu ≤ 3 (ngaphandle kwee-veneers ezibhityileyo), jonga uMzobo 3.4

Kwibhodi enemilo ekhethekileyo, qaphela uxhulumaniso phakathi kwebhodi yentombi kunye nebhodi yentombi, kwaye uzame ukwenza uxhulumaniso kwinqanaba ngalinye elihlukaniswe kumgca, njengoko kuboniswe kuMfanekiso 3.5.

03 pcb puzzle phezulu imiba elishumi efuna ingqalelo

Kwiimeko eziqhelekileyo, imveliso ye-PCB iya kubizwa ngokuba yi-operation ebizwa ngokuba yi-Panelization (Panelization), injongo kukunyusa ukusebenza kakuhle kwemveliso yomgca wokuvelisa i-SMT, emva koko i-PCB PCB, ziziphi iinkcukacha esifanele siziqwalasele? Makhe sijonge kunye.

1. Ifreyim yangaphandle (i-clamping edge) ye-PCB puzzle kufuneka yamkele uyilo oluvaliweyo lwe-loop ukuqinisekisa ukuba iphazili ye-PCB ayisayi konakala emva kokuba ilungisiwe kwifixture.

2. Imilo yephazili yePCB ikufutshane nesikwere kangangoko. Kucetyiswa ukuba usebenzise 2 × 2, 3 × 3,….

3. PCB panel ububanzi ≤260mm (SIEMENS umgca) okanye ≤300mm (FUJI line); ukuba unikezelo oluzenzekelayo luyafuneka, ububanzi bephaneli yePCB × ubude≤125mm × 180mm.

4. Ibhodi nganye encinci kwi-puzzle ye-PCB kufuneka ibe nemingxuma emithathu yokubeka ubuncinane, i-3 ≤ i-aperture ≤ 6 mm, i-wiring okanye i-patching ayivumelekanga ngaphakathi kwe-1 mm yemingxuma yokumisa edge.

5. Umgama ophakathi phakathi kwamacwecwe amancinci ulawulwa phakathi kwe-75mm ~ 145mm.

6. Xa ubeka i-reference positioning point, ngokuqhelekileyo ushiye indawo engena-solderless 1.5mm enkulu kunendawo yokumisa.

7. Kufuneka kungabikho zixhobo ezikhulu okanye izixhobo eziphumayo kufutshane neendawo zokudityaniswa phakathi kwesakhelo sangaphandle sepuzzle kunye nebhodi encinci yangaphakathi, naphakathi kwebhodi encinci kunye nebhodi encinci, kwaye kufuneka kubekho ngaphezu kwe-0.5mm yendawo phakathi imiphetho yamacandelo kunye nePCB Ukuqinisekisa ukuba isixhobo sokusika sisebenza ngokuqhelekileyo.

8. Imingxuma emine yokumisa ivuliwe kwiikona ezine zesakhelo sangaphandle sepaneli, kwaye ububanzi bomngxuma yi-4mm ± 0.01mm; amandla omgodi kufuneka abe yimodareyitha ukuqinisekisa ukuba ayiyi kuphuka ngexesha lamacwecwe aphezulu nangaphantsi. .

9. Iisimboli zereferensi ezisetyenziselwa ukumisa i-PCB kunye nokumiswa kwesixhobo esinophawu oluhle. Ngokomgaqo, ii-QFP ezine-pitch engaphantsi kwe-0.65mm kufuneka zibekwe kwiindawo zazo ze-diagonal; iisimboli zokuma zereferensi ezisetyenziselwa ukunyanzeliswa kweebhodi zentombi zePCB kufuneka zidityaniswe Sebenzisa, beka ngokwediagonal kwindawo yokubeka.

10.Amacandelo amakhulu kufuneka abe nezithuba zokubeka okanye imingxuma yokubeka, egxile kwi-interface ye-I / O, i-microphone, i-battery interface, i-micro.tshintsha, ujongano lwe-headphone, imoto, njl.