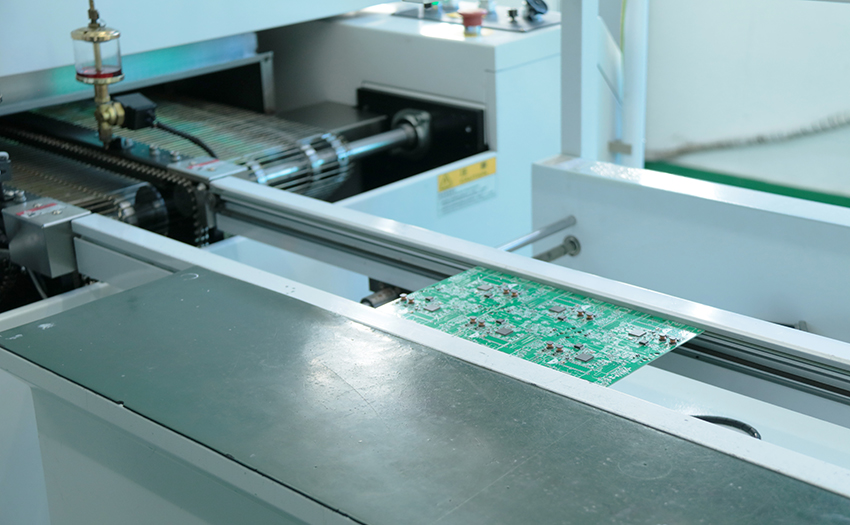

Ngemuva kwesikhathi sokufakwa okuqinile nokuhlelekile, ukuqeqeshwa nokusebenza kwemishini, ulayini wokukhiqiza we-SMT we-Shenzhen HDV photoelectron technology Co., LTD wafakwa ngokusemthethweni ekukhiqizweni ngo-Agasti 15, 2019. Ngaphambi kwalokhu, ngokukhiqizwa okuphelele kwebhodi le-SMT. , u-opharetha wezisetshenziswa ubesejwayelene nokugeleza kokusebenza kanye nezindawo zokusebenza zawo wonke amathuluzi.Okwamanje, isimo sokusebenza sihle.

I-SMT (Surface Mounted Technology) njengamanje iwubuchwepheshe obudume kakhulu kanye nenqubo embonini yokuhlanganiswa kwe-elekthronikhi. Kusukela ekuvakasheleni indawo yokusebenzela ye-SMT, inqubo yokukhiqiza ye-SMT ihlanganisa ikakhulukazi izinqubo ezimbalwa ezibalulekile ezifana nomshini wokunyathelisa ozenzakalelayo we-GKG, umshini wokubeka we-JUKI wase-Japan, ukugeleza kabusha. i-soldering, i-Shenzhou vision AOI, i-DIP wave soldering.Ukwenziwa okuqinile nokunemba kwenqubo ngayinye kuyimfuneko yokuqinisekisa ikhwalithi yomkhiqizo.

1.Isingeniso kumishini emikhulu:

⑴.Umshini wokuphrinta we-GKG ozenzakalelayo:

Nge-solder paste printing offset, umsebenzi wokuthola ukuphrinta okuzenzakalelayo, ungavimbela futhi ulawule u-70% weziphambeko ezivamile ekusebenzeni kwe-SMT.

Thumela umshini owodwa, ipuleti lokumunca elizenzakalelayo, dlulisela i-PCB esiteshini esilandelayo (umshini wokuphrinta ozenzakalelayo)

⑵.Japan JUKI Mounter:

Umshini wendawo yonke ufakwe ikhamera enembayo ephezulu ekwazi ukuhlonza izibopho ze-solder ze-BGA kanye nohlobo lwe-QFN, noma i-0.4MM pitch high edidiyelwe ye-SOP ne-PLCC.

Japan JUKI KE-2060 Mounter

⑶.I-Reflow soldering:

PCB ububanzi ububanzi: 500MM.

Izoni yezinga lokushisa: Indawo yokushisa eyisishiyagalombili ezimele nenembayo yokulawula izinga lokushisa, ijwayelana nazo zonke izinhlobo zamabhodi e-PCB, izingxenye nezinqubo.

Ngemuva kwe-reflow soldering, ingena esinyathelweni sokupholisa futhi ingabuye igcinwe okwesikhashana. Le nqubo ingagcina okwesikhashana 20pcs.

⑷.Shenzhou Vision AOI

Ukuhlola okuzenzakalelayo okuzenzakalelayo kokubona ngemva kwesithando somlilo, okunamandla okuthola ingxenye engu-0.6*0.3MM (0201), ikhamera yombala wase-Japan Ricoh 3CCD ingakwazi ukuhlonza ngokunembile ukushintsha kombala kwengxenye ngayinye, futhi iqhathanise futhi ibone kabi ngokuhlaziywa kokuqhathanisa, icubungula amaphuzu okuthola angu-180 ngomzuzwana, Ukulethwa okusheshayo nokulawulwa kwekhwalithi kuqinisekisiwe.

Umtshina we-AOI ungathola uhlobo lwengxenye kanye nomthelela wokushisela ngokuzitholela ngokuzenzakalelayo umkhiqizo omuhle kanye nomkhiqizo onesici.

2.Amandla omugqa wokukhiqiza

Ulayini ngamunye ungakhiqiza izinhlobo zezingxenye: izinhlobo eziyi-120 zangaphambili, izinhlobo ezingama-80 zangemuva, kanye nezinhlobo ezingama-40 zokuphakela amadiski we-MTS ukuze zisetshenziswe ngaphandle kokuphazamiseka, ingqikithi yezinhlobo zezingxenye ezingama-240.

Umthamo: 60000CPH umugqa ngamunye, ibalwa ngamaphuzu angu-150 nge-PCBA ngayinye, ingakhiqiza ama-400pcs ngehora, futhi ingakhiqiza i-PCBA 8000pcs ngosuku amahora angu-20.

Ngokwethulwa komugqa omusha wokukhiqiza, inkampani izofinyeza kakhulu isikhathi socwaningo nasekuthuthukisweni kokukhiqizwa kwe-prototype kanye nokukhiqizwa kokuhleleka kwamakhasimende. Isikhathi sokuhola semikhiqizo eminingi singalawulwa lingakapheli iviki elilodwa.

Ukwethulwa komugqa wokukhiqiza we-SMT kuzoxazulula ngokuphumelelayo inkinga yokushisela ezinye izingxenye ezingakwazi ukuthengiswa ngesandla ngesikhathi senqubo yokufaka ugesi yenkampani yethu, futhi kuthuthukise kakhulu ukusebenza kahle komsebenzi wokufaka ugesi, ikhwalithi yokushisela kanye nekhwalithi yokuhlola.