01 Kungani Indida

Ngemuva kokuthi ibhodi lesifunda seliklanyiwe, izingxenye zidinga ukubekwa emugqeni wokuhlanganisa we-SMT chip. Imboni ngayinye yokucubungula i-SMT izocacisa usayizi ofanele kakhulu webhodi lesifunda ngokuvumelana nezidingo zokucubungula zomugqa womhlangano. Isibonelo, ubukhulu buncane kakhulu noma bukhulu kakhulu, futhi umugqa womhlangano ulungisiwe. Ithuluzi lebhodi lesifunda alikwazi ukulungiswa.

Khona-ke umbuzo uphakama, kuthiwani uma ubukhulu bebhodi lethu lesifunda ngokwalo buncane kunobukhulu obunikezwe ifektri? Okusho ukuthi, sidinga ukuhlanganisa ibhodi lesifunda futhi sihlanganise amabhodi amaningi wesifunda abe ucezu lonke. Ukufakwa kungathuthukisa kakhulu ukusebenza kahle kokubili kwemishini yokubeka enesivinini esikhulu kanye ne-wave soldering.

02 Incazelo Yendida

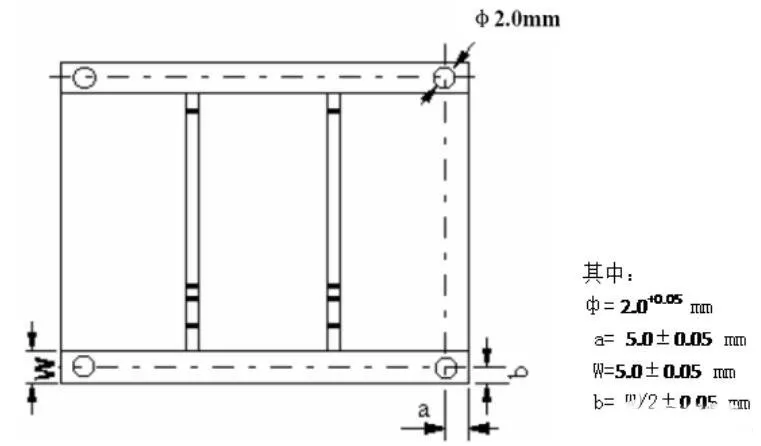

○ Ubukhulu

a. Ukuze kube lula ukucutshungulwa, i-engeli yebhodi le-veneer noma unqenqema lobuciko kufanele kube uhlobo lwe-R-chamfer. Ngokuvamile, ububanzi bekhona eliyindilinga ngu-Φ5.

b. Uma usayizi webhodi ungaphansi kuka-100mm × 70mm, i-PCB kufanele ihlanganiswe (bheka Umfanekiso 3.1).

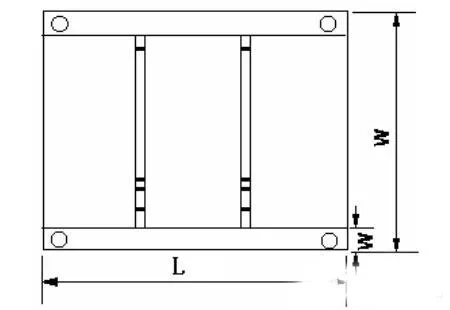

Izidingo zobukhulu bendida:

Ubude L: 100mm ~ 400mm

Ububanzi W: 70mm ~ 400mm

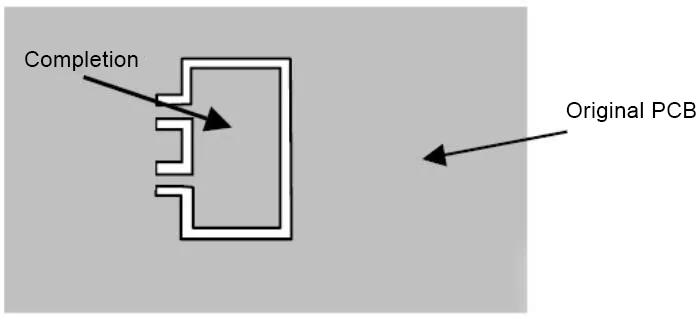

○ I-PCB engajwayelekile

Ama-PCB anomumo ongajwayelekile futhi awekho amajigi okufanele abe nemiphetho yobuciko. Uma i-PCB inezimbobo ezinobukhulu obukhulu noma obulingana no-5mm × 5mm, imigodi kufanele igcwaliswe ngesikhathi sokuklama ukuze kugwenywe ukunamathisela nokuguqulwa kwebhodi ngesikhathi sokuhlanganisa. Ingxenye ehambisanayo kanye nengxenye yokuqala ye-PCB kufanele ibe ohlangothini olulodwa Xhuma futhi uyisuse ngemva kokuhlanganisa amagagasi (bona Umfanekiso 3.2)

Uma ukuxhumana phakathi konqenqema lwenqubo kanye ne-PCB kuwumsele omise okwe-V, ibanga phakathi konqenqema lwangaphandle lwensiza kanye nomsele omise okwe-V ngu-≥2mm; lapho ukuxhumana phakathi konqenqema lwenqubo kanye ne-PCB kuyimbobo yesitembu, amadivaysi nemigqa akuvunyelwe ukuhlelwa ngaphakathi kuka-2mm eduze kwembobo yesitembu.

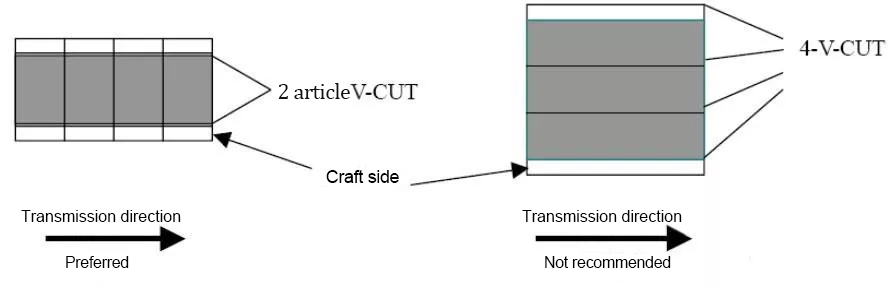

○ Indida

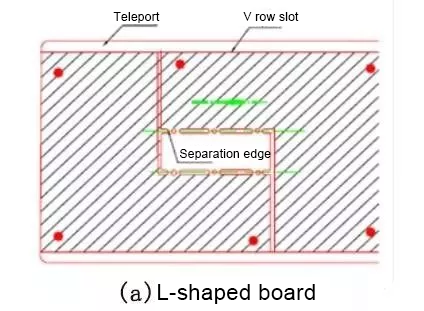

Isiqondiso se-jigsaw kufanele siklanywe ngokuhambisana nesiqondiso sonqenqema oludlulisayo. Lapho usayizi awukwazi ukuhlangabezana nezidingo ezingenhla zosayizi wokubekwa, okuhlukile. Ngokuvamile idinga i-“V-CUT” noma inombolo yemigqa yembobo yesitembu ≤ 3 (ngaphandle kwama-veneers azacile), bheka uMfanekiso 3.4

Ebhodini elimise okukhethekile, qaphela ukuxhumana phakathi kwebhodi lendodakazi kanye nebhodi lendodakazi, bese uzama ukwenza uxhumano esinyathelweni ngasinye sihlukaniswe emgqeni, njengoba kuboniswe kuMfanekiso 3.5.

03 pcb puzzle top izindaba eziyishumi ezidinga ukunakwa

Ngaphansi kwezimo ezijwayelekile, ukukhiqizwa kwe-PCB kuzobizwa ngokuthi ukusebenza kwe-Panelization (Panelization), inhloso ukukhulisa ukusebenza kahle kokukhiqizwa komugqa wokukhiqiza we-SMT, bese kuba yi-PCB PCB, yimiphi imininingwane okufanele siyinake? Ake sibheke ndawonye.

1. Uhlaka lwangaphandle (i-clamping edge) yephazili ye-PCB kufanele lusebenzise idizayini evaliwe ye-loop ukuze kuqinisekiswe ukuthi iphazili ye-PCB ngeke yonakale ngemva kokuba igxilile ku-fixture.

2. Ukuma kwephazili ye-PCB kuseduze nesikwele ngangokunokwenzeka. Kunconywa ukusebenzisa 2 × 2, 3 × 3,….

3. Ububanzi bephaneli ye-PCB ≤260mm (umugqa we-SIEMENS) noma ≤300mm (umugqa we-FUJI); uma ukukhishwa okuzenzakalelayo kuyadingeka, ububanzi bephaneli ye-PCB × ubude≤125mm × 180mm.

4. Ibhodi ngalinye elincane kuphazili ye-PCB kufanele libe nezimbobo okungenani ezintathu zokubeka indawo, 3 ≤ indawo yokuvula ≤ 6 mm, izintambo noma ukuphetshwa akuvunyelwe ngaphakathi kwe-1 mm yezimbobo zokumisa onqenqemeni.

5. Ibanga eliphakathi nendawo phakathi kwamapuleti amancane lilawulwa phakathi kuka-75mm ~ 145mm.

6. Uma usetha indawo yokuma kwereferensi, imvamisa shiya indawo engenaso umthengisi engu-1.5mm enkulu kunendawo yokuma.

7. Akufanele kube nezisetshenziswa ezinkulu noma izinto eziphuma eceleni eduze kwezindawo zokuxhumanisa phakathi kohlaka lwangaphandle lwephazili nebhodi elincane elingaphakathi, naphakathi kwebhodi elincane nebhodi elincane, futhi kufanele kube nesikhala esingaphezu kuka-0.5mm phakathi imiphetho yezingxenye kanye ne-PCB Ukuqinisekisa ukuthi ithuluzi lokusika lisebenza ngokujwayelekile.

8. Izimbobo ezine zokubeka zivulwa emagumbini amane ohlaka lwangaphandle lwephaneli, futhi ububanzi bembobo bungu-4mm ± 0.01mm; amandla omgodi kufanele abe ngokulinganisela ukuqinisekisa ukuthi ngeke aphule ngesikhathi samapuleti aphezulu naphansi. .

9. Izimpawu zereferensi ezisetshenziselwa ukuma kwe-PCB nokubeka idivayisi ngendlela ezwakalayo. Empeleni, ama-QFP anephimbo elingaphansi kuka-0.65mm kufanele abekwe ezindaweni zawo ezidayagonali; izimpawu zokuma zereferensi ezisetshenziselwa ukubeka amabhodi endodakazi ye-PCB kufanele amataniswe Sebenzisa, beka ngokudayagonali endaweni yokuma.

10.Izingxenye ezinkulu kufanele zibe nezikhala zokuma noma izimbobo zokubeka, zigxile ku-interface ye-I/O, umbhobho, isixhumi esibonakalayo sebhethri, imakrofoni.shintsha, isixhumi esibonakalayo samahedfoni, imoto, njll.